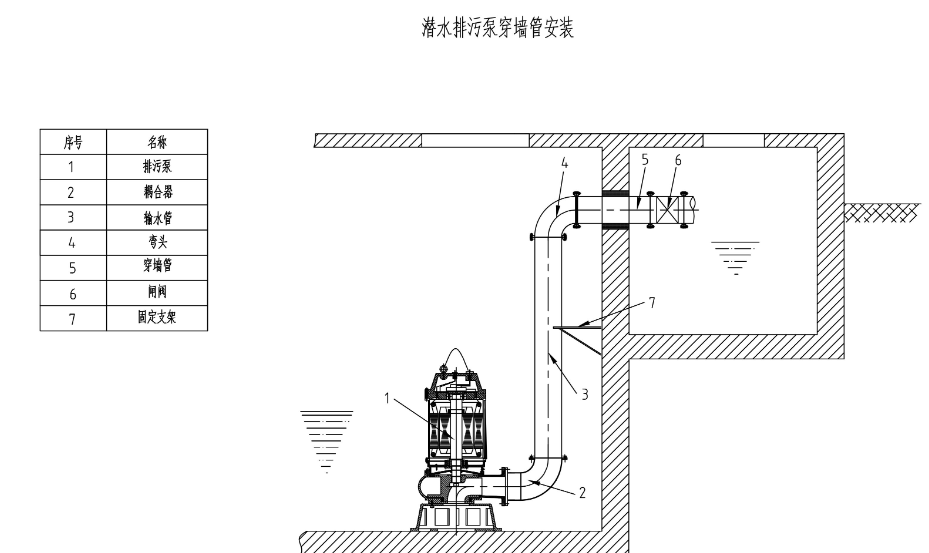

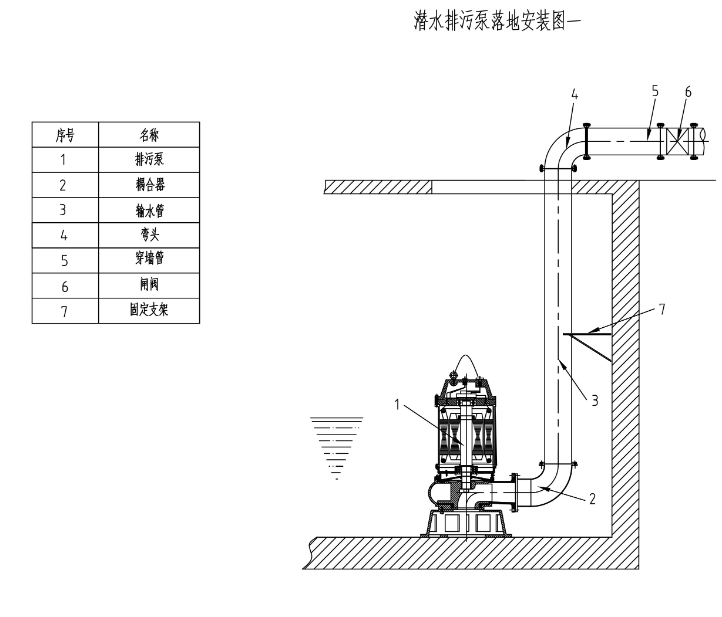

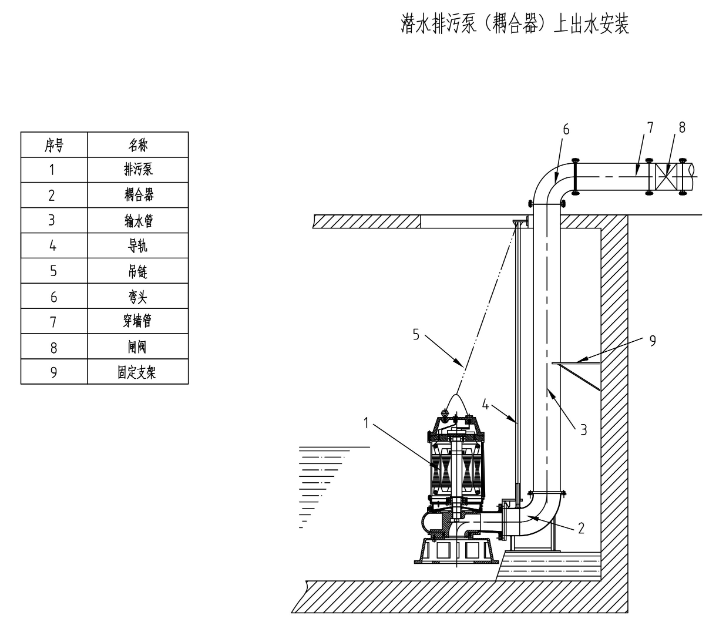

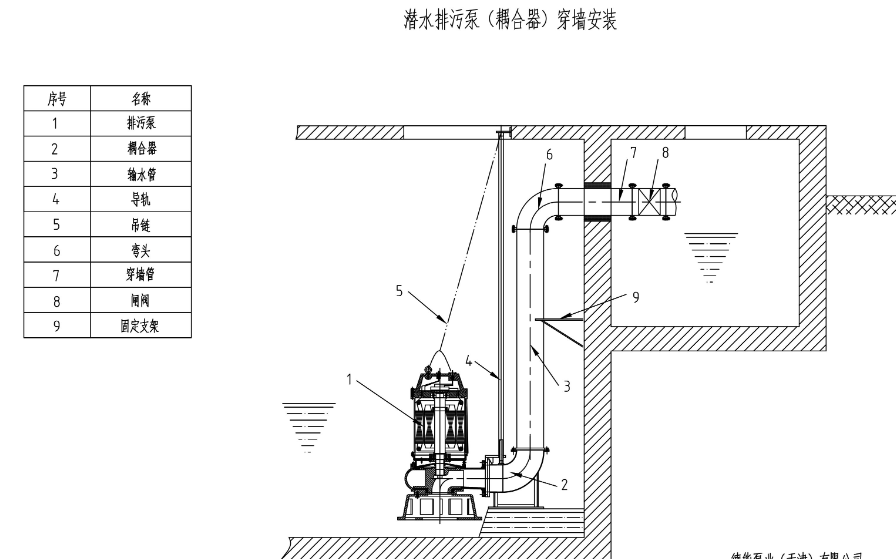

Submersible sewage pumps are used for discharging heavy sewage. They feature a large flow channel design, allowing for a particle flow rate of up to 10% of the outlet diameter. They offer high efficiency and are suitable for handling heavy sewage. Equipped with a coupling mechanism, they can be raised and lowered easily, eliminating the need for personnel to descend into the tank for operation and maintenance.

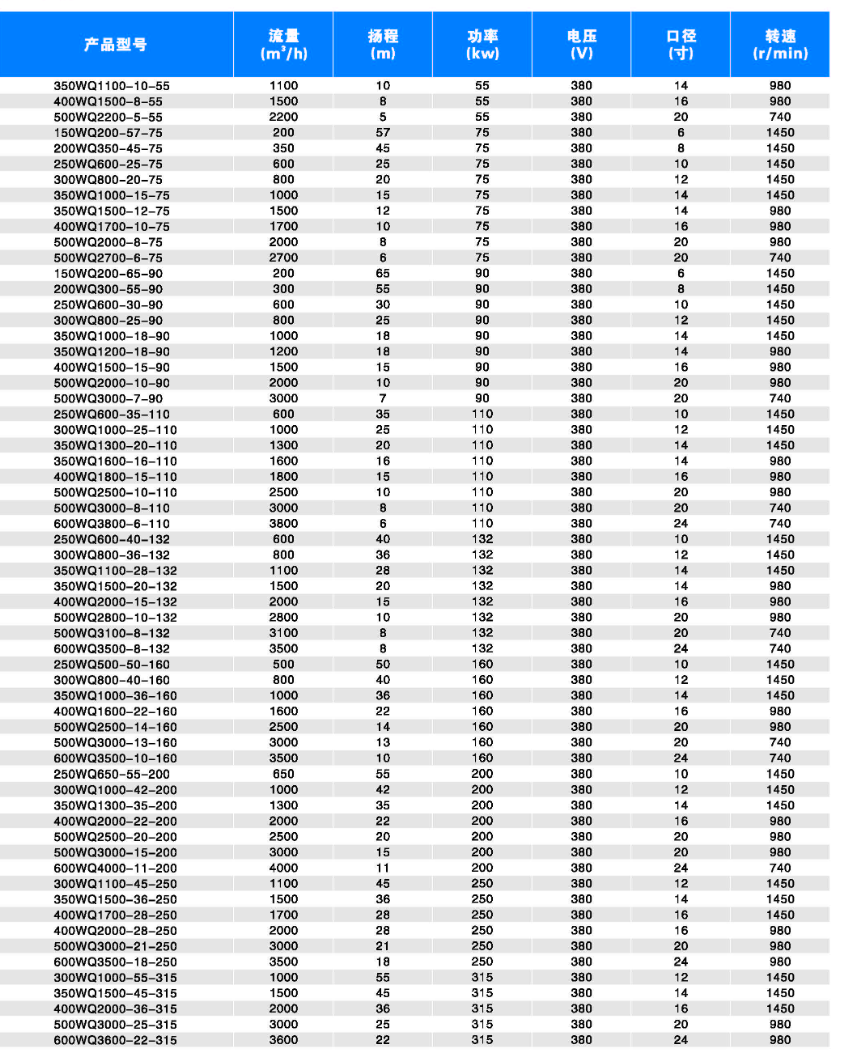

Power: 0.75-800 kW

Head: 1-60 m

Flow rate: 3-20,000 m³/h

Product Overview

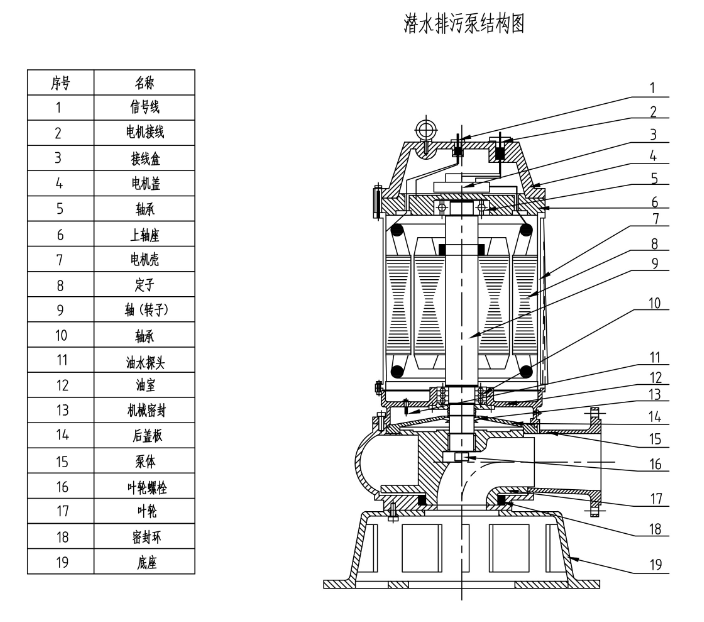

The WQ series sewage and wastewater submersible electric pump (hereinafter referred to as the pump) consists of a pump, seal, and motor. The motor is located above the electrical system and is available in single-phase and three-phase asynchronous motors. Double mechanical seals are used between the pump and motor, and each fixed seal uses an O-ring, oil-resistant rubber seal for static sealing. This series of pumps features a compact structure, high flow rate, high efficiency, and ease of use. Mechanical seals in key areas are made of carbide and silicon carbide, and the pump rotor shaft is tempered and hardened 45# steel. Stainless steel can also be used to ensure reliable mechanical strength and effectively improve shaft wear and corrosion resistance. This also facilitates impeller maintenance and disassembly. The entire series is available with an optional automatic coupling device. When the pump requires maintenance, it can be easily raised, lowered, disengaged, and engaged using a chain screw. This eliminates the need for personnel to enter the water for disassembly, significantly improving operational convenience and safety.

Main Applications

This series of electric pumps is widely used for sewage treatment, construction projects, hotels, miners, ponds, printing and dyeing, papermaking, textile processing, and other sewage and wastewater discharge. It is ideal for pumping slurries, mortars, domestic wastewater, sewage co-existence, and wastewater containing bulk particles such as fibers and paper scraps.

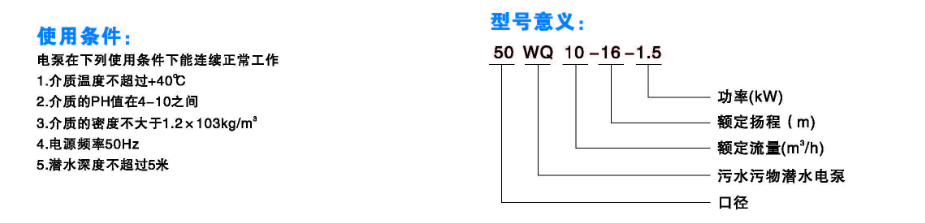

Usage Conditions

· Medium temperature not exceeding +40°C

· Medium pH between 4 and 10

· Medium density not exceeding 1.2 x 103 kg/m3

· Power supply frequency 50 Hz

· Submersible depth not exceeding 5 meters

Supporting Electric Cabinet Options

Auto-coupling step-down starter cabinet, soft starter control cabinet, variable frequency control cabinet, ultrasonic level meter, and PLC system

Technical Patents

KLS Pump Industry Co., Ltd. is a large-scale pump manufacturer integrating manufacturing, R&D, and project design. With over 40 years of product technology experience, KLS has introduced advanced domestic and international technologies and production equipment, continuously innovating in product R&D, and has developed a variety of new submersible pumps. These include: an automatically adjustable deep-well submersible pump, a mobile submersible mixed-flow pump with floating function, a high-lift submersible electric pump for deep wells, a mid-suction submersible mixed-flow pump, a submersible axial-flow pump with a sealing and anti-blocking mechanism, a water-lifting mid-suction submersible axial-flow pump, and a heat-resistant and corrosion-resistant submersible pump. All of these pump products have been granted utility model patents.

KLS Pumps has established a large-scale test bench, laboratory, water pump production ERP system, comprehensive data analysis server, and TP automated testing system. Leveraging its robust factory, technology, power supply equipment, and advanced testing equipment, test benches, and laboratory, KLS Pumps pioneered the concept of customized DIY production. Tianya Pumps offers customized design solutions and production of pumps tailored to specific water environments, engineering environments, and complex environments.