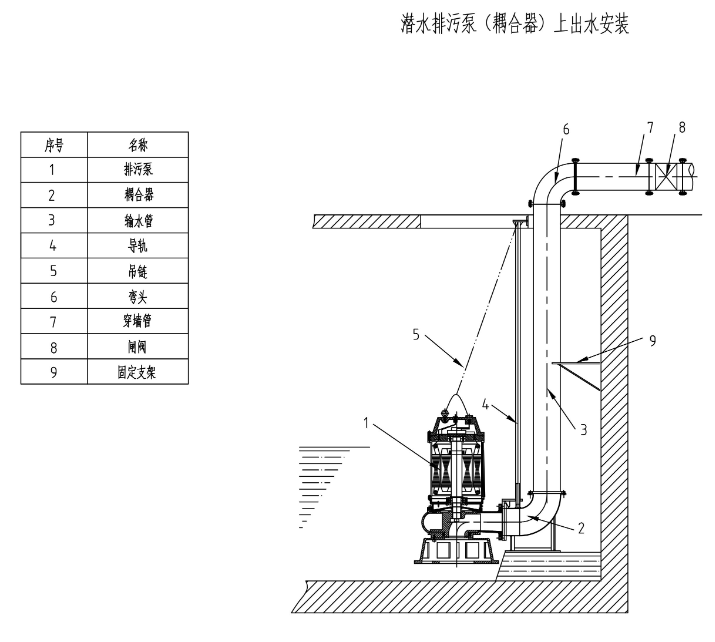

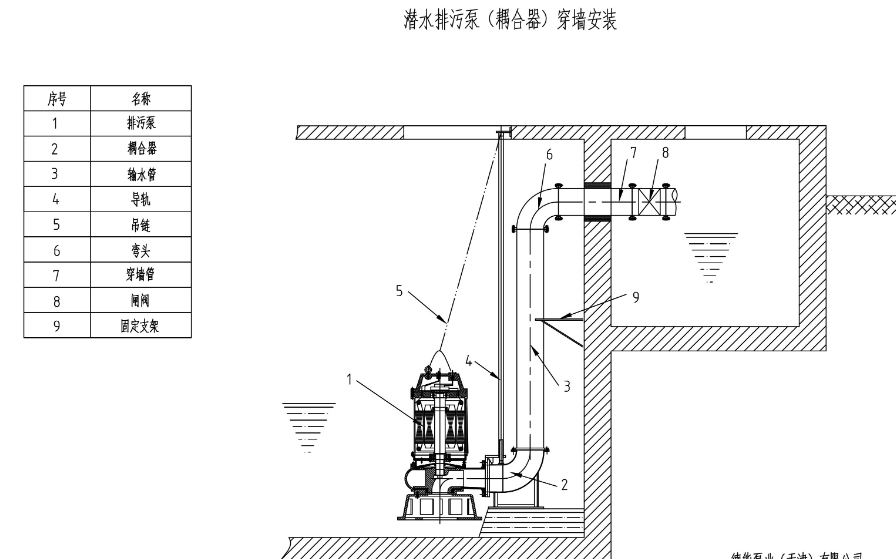

This corrosion-resistant and heat-resistant submersible sewage pump is designed for discharging wastewater at temperatures above 40°C. It features a large flow channel design, allowing for a particle flow rate of up to 10% of the outlet diameter. It offers high efficiency and is suitable for handling heavy sewage. Equipped with a coupling mechanism, it can be raised and lowered easily, eliminating the need for personnel to enter the tank for operation and maintenance.

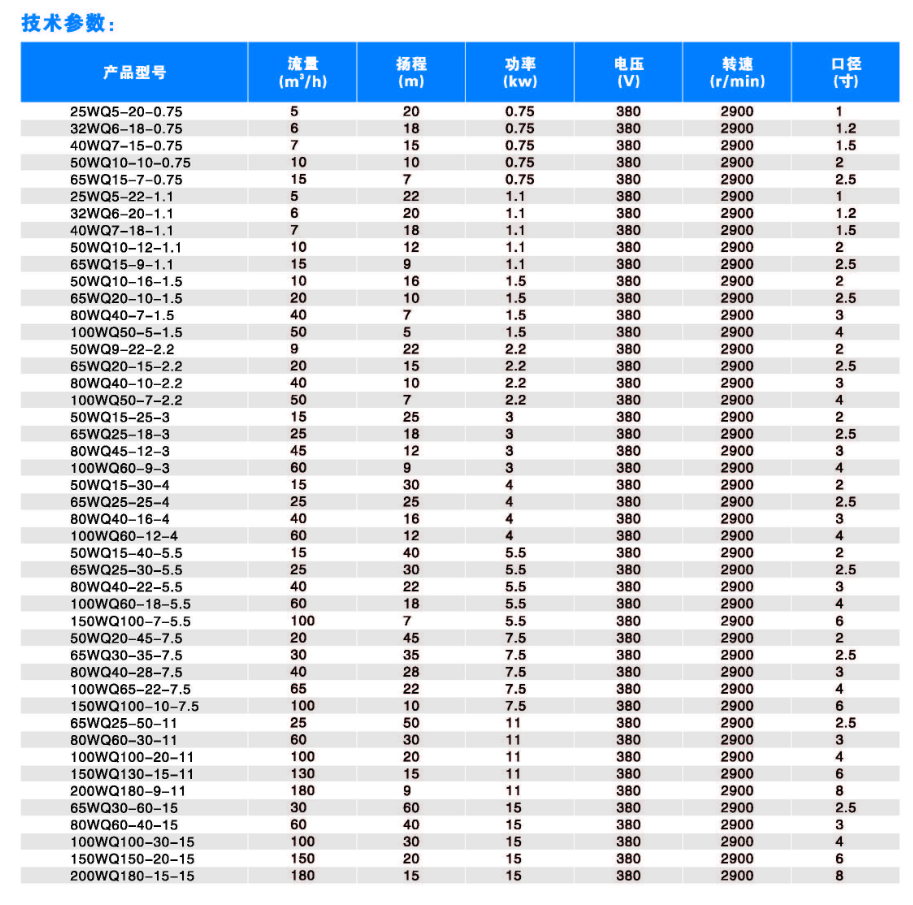

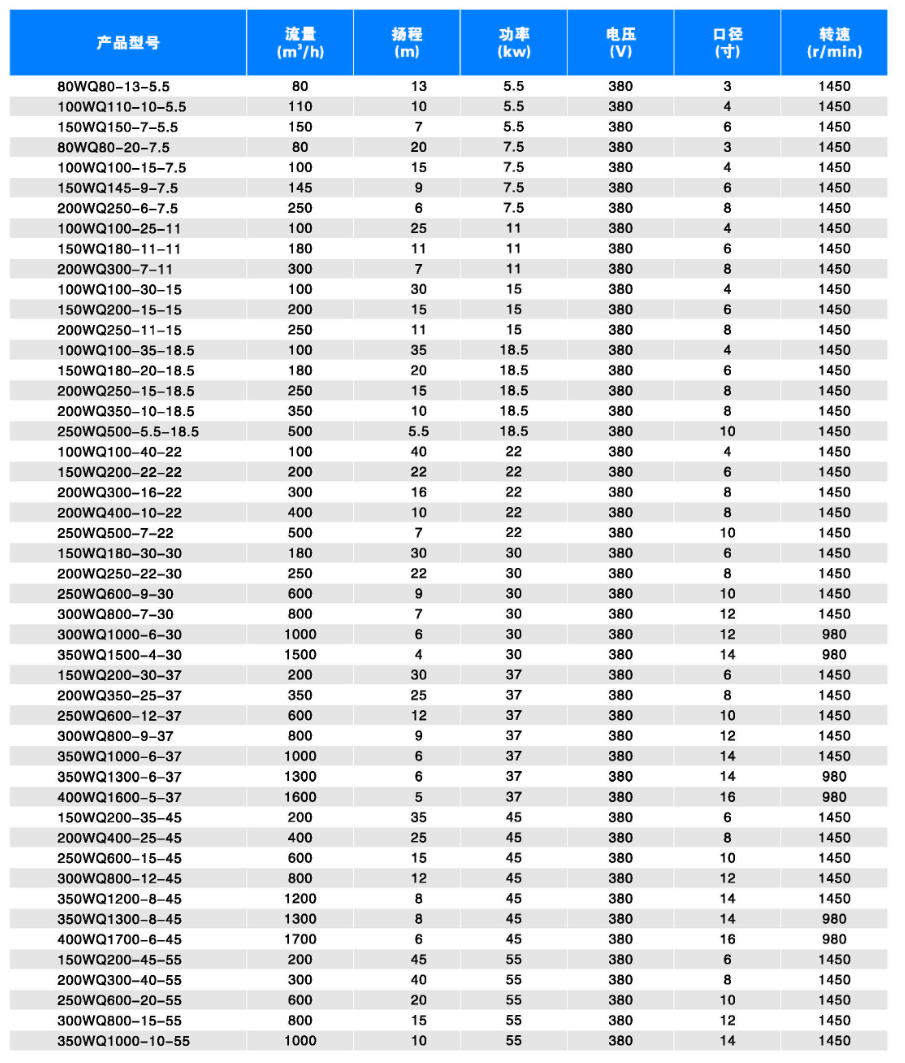

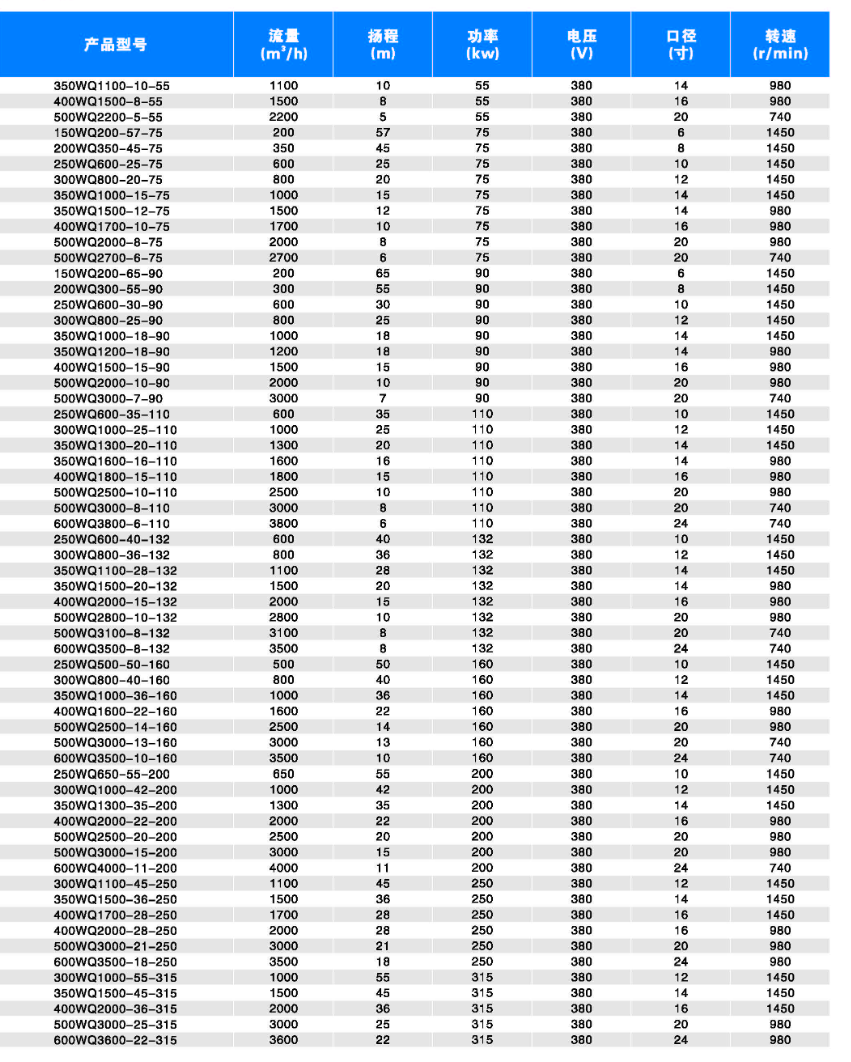

Power: 0.75-800 kW

Head: 1-60 m

Flow rate: 3-20,000 m³/h

Product Overview

This WQ(D) stainless steel, corrosion-resistant, and heat-resistant submersible sewage pump features a precision-cast stainless steel housing, offering corrosion resistance, environmental friendliness, high head, and high flow rates.

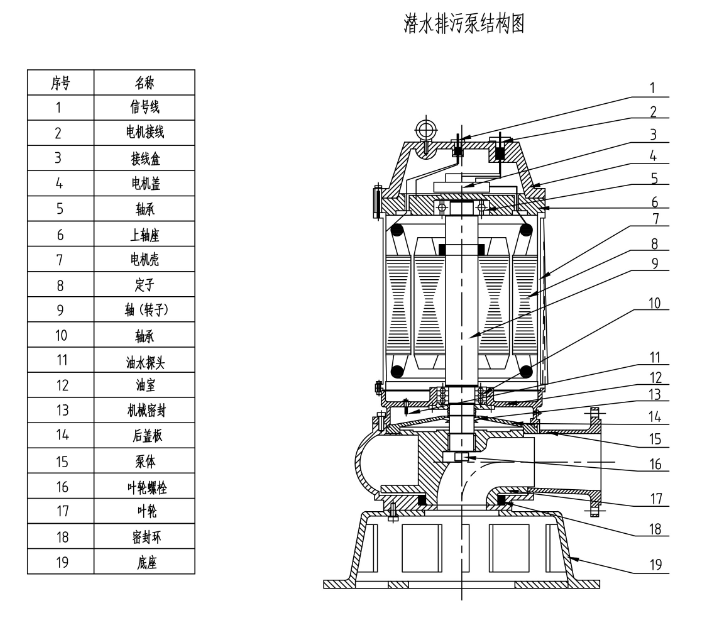

The oil chamber utilizes a double-sided fluororubber mechanical seal, while the outer chamber utilizes a single-sided fluororubber mechanical oil seal, effectively reducing water ingress caused by friction between the oil seal and the shaft.

The motor utilizes high-temperature wire, Class F insulation, and a thermal protector, effectively extending the pump’s service life.

Main Applications

Suitable for use in buildings, hospitals, residential areas, municipal engineering, road traffic and construction, factory sewage, aquaculture, pharmaceuticals, beverages, seawater, and general corrosive media containing solid particles, long-fiber wastewater, and sewage.

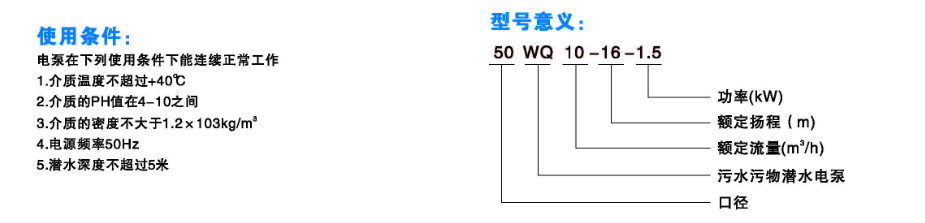

Usage Conditions

· The submersible depth must not exceed 5 meters, based on the impeller center.

· The pumped medium temperature must not exceed 60°C.

The pH value of the conveying medium is 304 (4-10), 316 (2-13).

The kinematic viscosity of the conveying medium is 7×10-7~23×10-6m2/s.

Supporting Electric Cabinet Options

Autocoupler step-down starter cabinet, soft start control cabinet, frequency converter control cabinet, ultrasonic level meter, and PLC system.

Technical Patents

KLS Pump Industry Co., Ltd. is a large-scale pump company integrating manufacturing, technology research and development, and project design. With over 40 years of product technology experience, KLS has introduced advanced domestic and international technologies and production equipment, continuously innovating in product research and development, and has developed a variety of new submersible pumps. These include: an automatically adjustable deep-well submersible pump, a mobile submersible mixed-flow pump with floating function, a high-lift submersible electric pump for deep wells, a medium-suction submersible mixed-flow pump, a submersible axial-flow pump with a sealing and anti-blocking mechanism, a water-lifting submersible axial-flow pump, and a heat-resistant and corrosion-resistant submersible pump. All of these pumps have been granted utility model patents.

KLS PUMP boasts a large-scale test bench, laboratory, pump production ERP system, comprehensive data analysis server, and TP automated test system. Leveraging its robust factory, technology, power supply equipment, and advanced testing equipment, test benches, and laboratory, Tianya Pump Industry pioneered the concept of customized DIY production. KLS PUMP offers customized design solutions and production of pumps tailored to specific water, engineering, and complex environments.